A look at the headlines from across the country, along with a review of the Occupational Health and Safety Association (OSHA) website, reveals that there has been a significant increase in the number of serious bridge construction accidents over the last few years.

Many led to serious injuries and deaths. In most cases, these incidents could have been prevented if rules, regulations, and best practices had been strictly followed.

In this article, we’ll explore the causes of a few recent bridge construction accidents and see what we can learn from them about improving construction site safety. We’ll also look back at some of history’s biggest calamities and explore how they contributed to current safety standards.

Recent Bridge Construction Accidents

1 . Liberty Bridge Construction Fire

Pittsburgh, Pennsylvania

September 2, 2016

What happened:

The Liberty Bridge is an aging structure built in 1928 that crosses the Monongahela River in Pittsburgh. It is a busy commuter artery that connects downtown with the Liberty Tunnels that lead out to the suburbs. It has recently been undergoing badly needed rehabilitation work. The deck was in the process of being replaced when a worker using a welding tool ignited a tarp. The ensuing fire spread quickly and heated up when it started burning plastic piping that was part of the bridge infrastructure.

The fire grew large enough to significantly damage a 30-foot-long support girder. Officials had serious concerns that the compromised support, even though it affected a limited section of the bridge, could lead to a catastrophic bridge failure.

Work began immediately on design solutions to remedy the issue, and limited traffic was restored within three weeks. Construction has been able to continue on rehabilitating the bridge.

What we can learn:

Two important lessons can be learned from this construction disaster.

First, anyone working with dangerous equipment on a construction site must always follow best safety practices. This fire could have been avoided if the welder had not been working too close to a flammable tarp.

Second, it’s important that all bridge infrastructure, including the piping and wiring that carry utilities across bridges, are made of safe materials and that they are adequately shielded and protected. This is a big issue on aging bridges, where older infrastructure may not satisfy today’s more stringent building codes.

Contact an expert to learn the latest about installing safe utility infrastructure on bridges. This is an important step toward greater overall bridge safety.

2. Construction Crane Collapses on Tappan Zee Bridge

Westchester, New York

July 19, 2016

What happened:

A massive 25-story construction crane was being used to build a new bridge next to the existing Tappan Zee Bridge on the Hudson River in New York State. It was connected to a 60-ton vibrating hammer that drove pilings for the new bridge into the river bed. Suddenly, one afternoon, its boom failed and crashed onto the existing bridge.

The accident was completely unexpected. The task being performed by the crane and hammer had become routine. Almost half the pilings for the new bridge had already been installed using the same equipment and process.

Since the weather was good at the time and winds were mild, it is unclear what caused the collapse, although operator error has been ruled out. An initial theory is that the pile that was being hammered into place struck a particularly soft spot in the river and started to sink rapidly. This action jolted the giant hammer into a fast drop, which strained the boom on the crane and caused it to buckle and fall.

Despite the fact that the accident occurred on an active construction site during a busy traffic period, only a few people suffered relatively minor injuries.

What we can learn:

The OSHA investigation of this accident is still underway. However, some have questioned the braking capabilities of the crane and the fact that it was positioned so close to a high-traffic area. A crane that provided greater braking control to the operator might have been stopped more quickly, preventing the accident. Many experts have also expressed concerns about whether this was the right size and scale of machinery to be used so close to a major commuter bridge.

If you have questions about the proper use of heavy equipment on a bridge construction site, an experienced equipment supplier can answer them. It could make all the difference when it comes to the safety of your job sites.

3. Beam Falls from I-90 and Touhy Road Bridge

Des Plaines, Illinois

April 5, 2016

What happened:

Bridge workers were in the process of removing a massive 180-foot-long, 45-ton beam from the bridge. While cutting some steel bracing, the beam collapsed after a support chain or strap failed. Two beams had already been removed from the structure successfully before this incident occurred.

One construction worker was killed and three others injured.

What we can learn:

OSHA is still looking into what caused this accident. Initial indications show it was highly preventable. More than likely, adequate support could have kept the beam from collapsing. In addition, equipment that provides more flexible access to the underside of a bridge may have kept workers out of harm’s way.

This is a good lesson that safety guidelines must always be followed. Inadequate protection can lead to fatal accidents.

4. Collapse of a Bridge Onto Southbound Interstate I-75 During Demolition

Cincinnati, Ohio

January 19, 2015

What happened:

The center and east spans of a ramp bridge that was in the process of being demolished unexpectedly fell almost 20 feet onto the I-75 south freeway. When the late-night incident occurred, a concrete slab was being removed from the deck of the ramp.

Demolition work had started a day earlier. It was stopped because there were concerns about steel girders lifting off their bearings. Remedial measures were recommended by engineers involved with the project. They were carried out and work continued. However, these proved to be inadequate when the collapse occurred.

One worker was killed and another injured.

What we can learn:

The OSHA analysis of this incident is a damning one.

A verbal, non-documented plan on how to remove concrete from the structure was flawed. Computations indicate that under the plan, support girders were subjected to an unacceptable level of uplift force. An analysis showed that as the concrete load was being removed, the steel girders would rise from the abutment. Unfortunately, the plan did not call for the girders to be tied down at the abutments.

A last-minute recommendation by the project engineers to physically tie down the girders was inadequate and did not meet industry design standards. This caused the ultimate failure.

OSHA cited poor planning and inadequate remedial action as the cause of the collapse.

5. Collapse of Two Pedestrian Bridges Under Construction at Wake Technical Community College

Raleigh, North Carolina

November 13 and 14, 2014

What happened:

A pedestrian bridge under construction on a college campus suddenly collapsed while a concrete walkway was being poured on a metal deck. A day later, a similar bridge that was also under construction a block away collapsed as well. No construction was taking place at the time of the second incident.

Both bridges were built of glued laminated timber girders and trusses that blended in with their natural surroundings.One worker was killed and four injured in the first incident, none in the second.

What we can learn:

In the case of these two bridges, a small design flaw led to big consequences. Notches were placed at the end of the glued laminated timber girders to make it easier to connect them. The notches failed under a full load of concrete because the weight of it caused large horizontal cracks in the wood that started near the notches.

OSHA came to the conclusion that the large number of engineers, consultants, and contractors who reviewed the plans for the bridges should have caught the design flaw, which was not within construction standards.

This is a lesson for bridge engineers on the importance of not just looking over plans when reviewing them but actually closely checking them for design issues.

Historic Bridge Construction Accidents

6. Scaffolding Accident on the Golden Gate Bridge

San Francisco, California

February 16, 1937

What happened:

Back when the Golden Gate Bridge was built, construction safety statistics were grim. On average, one person would die on a job site for every million dollars spent on a high-altitude, steel-based construction project. That’s why Joseph Strauss, the chief engineer of the Golden Gate construction project, invested hundreds of thousands of dollars (a significant amount at the time) on enhanced safety measures for his workers.

These measures included providing workers with hard hats and requiring that they be worn on the job. He also demanded that workers be completely sober on the job and not perform stunts or antics, a common practice at the time.

The biggest and most expensive safety enhancement was the installation of a huge net, similar to the type used under trapeze acts, under the bridge. It extended more than 10 feet beyond the length and width of it.

This innovation provided an enhanced level of worker safety and actually helped speed bridge construction because workers felt more confident walking along the open steel structure, knowing there was protection below.

Unfortunately, a construction accident proved the net was vulnerable. A platform holding 11 workers collapsed, sending them and several others into the net. Shortly after, a scaffolding fell off a support rail and landed in the net, causing it to tear. Most of the workers fell more than 20 stories into the water below. Ten of them perished.

What we can learn:

Bridge contractors learned a great deal about safety from the Golden Gate Bridge accident. First, they started implementing duplicative safety systems, such as using safety cables in addition to nets. Also, it was the beginning of the development of safer equipment that reduced the need to use platforms during the construction process.

Today, equipment like the Bridgewalker, Hydra Platform, and Paxton Mitchel Snooper make it easier and safer to get to hard-to-reach areas of bridges during the construction and inspection processes. They’re particularly valuable when it comes to installing utility infrastructure below bridges.

7. Big Four Bridge Construction Accidents

Louisville, Kentucky and Jeffersonville, Indiana

1888-1895

What happened:

The Big Four Bridge is a former railroad truss bridge that crosses the Ohio River. It is currently used as a pedestrian and bicycle bridge. Today’s benign use belies its reputation as one of the most dangerous projects in bridge construction history.

Work began on the bridge in 1888, before there were guidelines available to govern bridge construction safety. Many serious accidents happened, and 37 people died while it was being built.

Twelve drowned while working on a pier foundation when a caisson (an underwater structure that keeps out water) that was supposed to hold back the river water flooded. Four people died when a wooden beam broke while working on another caisson.

Twenty-one workers died and another 20 were injured when a construction crane was dislodged by a severe wind, causing a truss to be damaged. The 41 workers on the truss fell into the Ohio River. More lives would have been lost if a ferry crossing the river very close to the site of the accident had been hit by the truss.

What we can learn:

The terrible accident history on this project resulted in significant immediate and long-term reforms.

Bridge falsework was reinforced to prevent more accidents. In addition, special bracing was added to the bottom frame of trusses. Also, a new rule was implemented on the job site and enforced: “Never trust a bolted joint any longer than is necessary to put a riveted one in place.”

The accidents ushered in a period of construction safety reform that opened the door to OSHA being created.

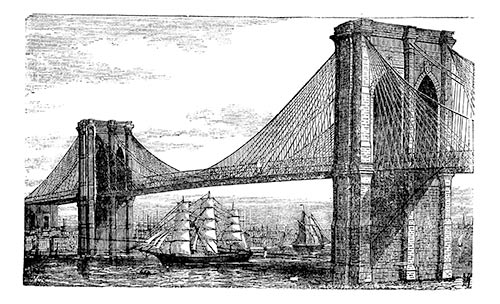

8. Accidents During Construction of the Brooklyn Bridge

Brooklyn, New York

1883

What happened:

The Brooklyn Bridge is a New York icon. Construction took 14 years. More than 600 workers were involved. A remarkably high percentage of them, more than two dozen, died in the process.

To build a foundation for the bridge, workers excavated the riverbed in giant wooden boxes called caissons. These airtight devices were held firm to the river’s floor by large granite blocks. Pressurized air was pumped into them to keep water and pollutants out.

Workers called “sandhogs” used picks, shovels, and dynamite to clear the mud and rocks at the bottom of the river in order to reach the bedrock. Once they did, they laid granite blocks for the bridge foundation, working their way back up to the surface.

When the workers were in the caissons, they experienced excruciating headaches, itchy skin, bloody noses, and slowed heartbeats. Getting to the caissons was even worse. The sandhogs rode in small iron containers called airlocks. They were filled with compressed air as they were lowered into the river, which made it possible for workers to breathe and to keep water from rushing in. It also allowed a dangerous amount of gas to enter the workers’ bloodstreams. When the workers resurfaced, the gases in their blood were quickly released.

This caused a disease known as the bends. The symptoms include severe joint pain, paralysis, convulsions, numbness, and speech issues. Many died from it. In addition, other construction accidents on the project, such as collapses, fires, and explosions led to more deaths.

What we can learn:

It took until early in the 20th century for doctors and scientists to figure out that if airlocks travel from the bottom of a body of water to its surface more slowly, it prevents the bends. In 1909, New York passed the nation’s first caisson-safety laws to protect underwater workers. In addition, the state has been a pioneer in passing other construction safety legislation.

Conclusion

Focusing on safety on bridge construction sites is critical. It protects workers from illnesses, injuries, and death and helps keep jobs on schedule by avoiding accident-related delays. Three things you can do to improve safety include:

- Carefully following all federal and local safety guidelines.

- Ensuring all workers stay compliant at all times.

- Using the right equipment to keep workers safe.

If you have questions about bridge construction safety and the right equipment to use to keep workers safe, consult with an expert on bridge construction, maintenance, and utility installation.