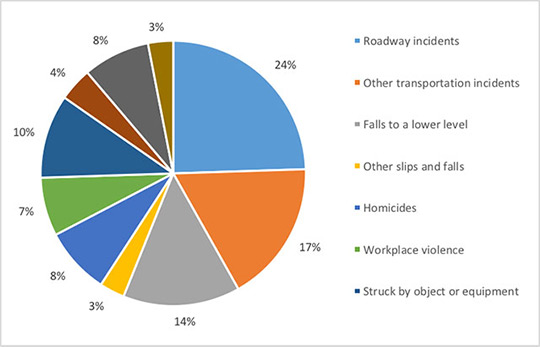

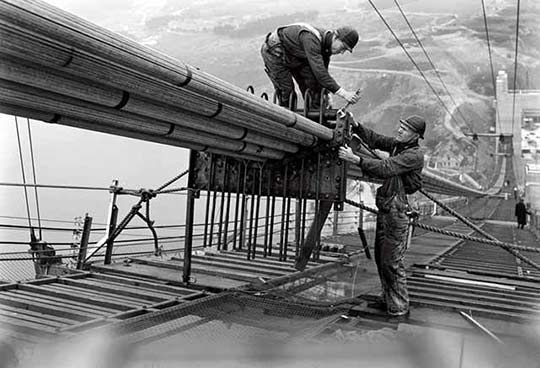

Despite significant advancements in bridge construction safety, working on bridges remains inherently risky. Before the Occupational Safety and Health Administration (OSHA) was established, approximately 14,000 workers lost their lives annually on the job. Today, that number has decreased to about 12 per day, but even one is too many. Transportation-related incidents account for over 40% of workplace fatalities, highlighting the need for stringent safety measures.

Even with a downward trend in workplace deaths over the decades, certain years have seen increases due to factors like exposure to harmful substances, falls, slips, trips, and transportation accidents. These statistics underscore the importance of continuous improvement in safety protocols.

Researchers and manufacturers are continually developing tools, protective gear, and equipment designed to keep workers safe. Here are ten essential safety tools that should be utilized on every bridge construction site:

1. Specialized Bridge Access Equipment

One of the most significant risks for bridge workers is falling from elevated areas. This often occurs when workers use inappropriate equipment to access hard-to-reach sections. To mitigate this risk, it’s crucial to use equipment specifically designed for bridge access:

- BridgeWalkers: Securely lower workers up to 20 feet below a bridge, even in confined spaces.

- Hydra platforms: Allow movement of workers up to 35 feet below a bridge, featuring a rotatable work platform for easy access to bridge edges.

- Paxton-Mitchel snoopers: Provide safe access to the most challenging areas of large bridges.

- UBITs: (Under Bridge Inspection Trucks): Highly flexible articulated units that can lower workers almost 26 feet below the bridge deck.

Each type of under bridge access equipment serves a specific need in bridge construction. Collaborating with a reputable firm can help determine the appropriate equipment for your project.

Tip: If budget constraints are a concern, consider hydra platform rental options to access the necessary equipment affordably. Learn more.

2. Eye and Face Protection

OSHA mandates that bridge workers use eye and face protection, including safety glasses and face shields, at all times. Injuries often result from foreign objects entering the eye during activities like welding, cutting, grinding, nailing, or working with concrete. Additional hazards include extreme winds, sparks, smoke, and exposure to dangerous chemicals.

Employers must ensure that all employees exposed to eye or face hazards from flying particles, molten metal, liquid chemicals, acids, chemical gases, vapors, or potentially injurious light radiation use appropriate eye or face protection. For comprehensive guidelines, refer to OSHA’s recommendations on construction eye protection.

3. Fire Blanketing

Serious injuries can occur when utility lines, cables, and piping on bridges are damaged by construction equipment. Having fire control tools readily available, such as fire blankets made of fire-retardant material, is essential. These blankets can smother fires effectively, especially electrical or utility-related ones.

4. Foot Protection

Workplace accidents related to slips, trips, and falls have seen significant increases. One preventive measure is ensuring workers wear the correct footwear. OSHA requires employers to provide protective footwear when there’s a risk of foot injuries from falling or rolling objects, potential sole penetration, or exposure to electrical hazards.

Investing in OSHA approved work boots can significantly reduce the risk of foot-related injuries on the job site.

5. Under-Bridge Protection

Bridge utility lines are vulnerable to damage from construction equipment, tampering, weather incidents, and natural disasters. Protection Under Bridge (PUB) systems are caging units designed to shield these utility lines, ensuring continuous service and enhancing safety for both workers and the community. Contact an expert on these systems to find out how installing them could make the bridges you work on safer.

6. High-Visibility Safety Equipment

Workers on bridges and roadways must wear high-visibility clothing to remain visible to drivers, thereby preventing accidents. The American National Standards Institute (ANSI) provides guidelines for such apparel under ANSI/ISEA 107-2010. These garments offer varying levels of protection based on the work environment.

Tip: Adhering to ANSI standards for care and maintenance ensures the longevity and effectiveness of reflective safety clothing.

7. Hand Protection

According to the CDC, workplace hand injuries account for over a million emergency medical visits annually in the U.S. The Bureau of Labor Statistics reports that hand injuries, including cuts and punctures, cost the construction industry $382 million each year.

Notably, 70% of injured workers weren’t wearing gloves, while the remaining 30% wore inadequate or damaged gloves. OSHA’s guidelines emphasize the importance of appropriate hand protection when exposed to harmful substances, sharp objects, severe abrasions, burns, or extreme temperatures. A Liberty Mutual Research Institute for Safety study found that wearing gloves reduces hand injury risk by 60 percent.

Modern gloves made from high-tech materials offer superior protection and comfort, with some providing up to 300% more abrasion and cut resistance than traditional leather gloves.

8. Head Protection

OSHA requires the use of hard hats on bridge sites to protect against falling objects, head bumps, and electrical hazards. Modern hard hats, often made from high-density polyethylene (HDPE) or advanced engineering resins, may include features like ventilation, face shields, sun visors, earmuffs, and other accessories to enhance safety and comfort.

Did you know? The MSA V-Gard GREEN Helmet is the first industrial safety helmet produced from nearly 100% renewable resources, utilizing HDPE sourced from sugarcane ethanol.

9. Signage and Barriers

Implementing adequate signage and appropriate barriers is crucial for protecting workers on bridge construction sites. OSHA standards mandate the use of traffic control signs, signals, barricades, or devices to safeguard construction employees from traffic hazards.

Tip: Deploy temporary traffic control signs and barriers shortly before construction begins to maintain driver alertness and prevent complacency.

10. Safe Vehicles

A significant number of fatalities in bridge and road construction zones result from workers being struck by construction equipment or vehicles. Ensuring all on-site vehicles are equipped with safety features is vital:

- Functional headlights and brake lights

- Windshield wipers and defogging/defrosting devices

- Audible horns and back-up alarms

- Undistorted safety glass

- Proper mirrors

- Adequate seating and seat belts

Regular inspections of equipment and safety features are essential to maintain optimal working conditions.

Did you know? Over 40,000 people are injured annually due to crashes in work zones, equating to one injury every nine minutes. (OSHA)

Final Thoughts

Injuries and fatalities on bridge construction sites are preventable. By utilizing the appropriate equipment and adhering to safety protocols, workplace risks can be significantly reduced. Prioritizing the safety of your employees is not only the right thing to do but also makes sound business sense.

For more insights on bridge construction safety, explore our post on handling bridge emergencies.

“Making a living shouldn’t have to cost you your life. Workplace fatalities, injuries, and illnesses are preventable. Safe jobs happen because employers make the choice to fulfill their responsibilities and protect their workers.” — Dr. David Michaels

Assistant Secretary of Labor for Occupational Safety and Health